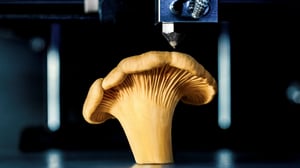

Researchers at the Singapore University of Technology and Design have developed a cutting-edge 3D printer that can create good, healthy food that looks delicious, using a very diverse selection of ingredients as well as waste.

Like in a science fiction film, researchers at the Singapore University of Technology and Design, in a country that has been at the forefront of innovation in food for years, have developed a 3D printer capable of creating à la carte food with an incredibly diverse selection of ingredients, and with the desired texture, colour and appearance.

This means being able to create food to suit all needs, at least in theory. For example, the printer can produce food suitable for people on low-fat diets, those with diabetes, or who need more of a certain vitamin or mineral in their diet, those who need to modify their microbiota (all the ‘good’ gut bacteria) with specific probiotics for preventive reasons, or people with swallowing difficulties. It can also print products for anyone wanting to try foods that don’t exist in nature, or for those who appreciate food with a particular appearance. But that’s not all. Being able to shape food also means making the best possible use of proteins and other nutrient groups that don’t appeal to consumers in their natural form or would normally go to waste, as is the case with most insects, the dregs from soybean processing, or citrus fruit peel, which are all highly nutritious and should therefore be leveraged. By adjusting the settings, the printer could be used to create an aesthetically pleasing meal from these unusual sources.

Innovative nozzles

As the researchers explained in the scientific journal Future Foods, the technological breakthrough of the novel printer is its ability to blend together ingredients with very different textures and physical and chemical properties, to produce a single homogeneous food. All devices made up until now have only been able to work with a single ingredient (and a very common one at that, such as chocolate, milk, fruit or vegetable purées, and gelatins), due to the difficulty in getting the ‘machine’ to interact with materials that are very different from each other. In particular, attempts to combine ingredients were based on multiple nozzles that held, and then ejected, the various constituents needed to produce the desired result (a bit like having lots of colouring pencils to create a drawing). This required perfect nozzle alignment during printing, which is very difficult to achieve, often with disappointing results." The researchers in Singapore, on the other hand, opted for multiple inlet channels and a single outlet nozzle, with mixing performed inside the printer to create a homogeneous substance.

Even the QR code becomes edible

To overcome problems due to the different viscosity and elasticity properties of the materials used, the bioengineers altered the shape of the outlet nozzle and the algorithm that defined the printer’s movements, to achieve continuous output. They also succeeded in minimising ‘backflow’ into the printer (one of the major limitations of existing models is that ingredients can flow back inside, depending on their greater or lesser ability to resist flow, clogging the nozzles and spoiling the end product).

And there’s more: the printer is so precise that it can even create a perfectly functioning QR code with all the nutritional information. A code you can scan, then eat...